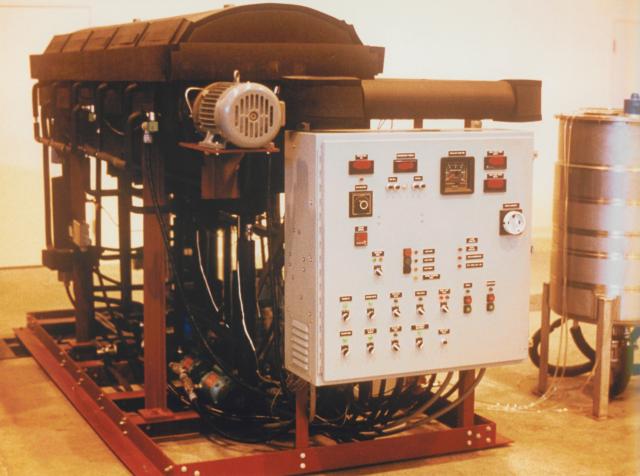

5-effect WFRD Pilot System

This system was installed at a West Texas oil well to demonstrate the system capability to reclaim high quality distilled water from produced water with a TDS of 100,000 ppm. Distillate quality was less than 150 ppm !!

The Wiped-Film, Rotating-Disk (WFRD) evaporator is the core component of our distillation system. It was developed to improve energy efficiency, and minimize equipment capital cost over that of traditional distillation and desalination technologies.

Current off-the-shelf evaporator technology is comprised of fixed heat transfer surfaces – primarily horizontal or vertical tube bundles, or vertical plates. These designs typically result in overall heat transfer coefficients (OHTC) in the range of 200 to 500 Btu/hr ft2 °F. The WFRD uses a combination of rotating disks and fixed wipers in its evaporator design, thereby achieving an order of magnitude improvement in OHTC, and resulting in a very significant reduction in specific energy consumption, as well as reduction in plant size. Another unique feature is its proprietary self-cleaning mechanism within the evaporator. This significantly reduces service requirements due to fouling, and greatly improves plant availability (on-line time). Plant availability is an extremely valuable feature of any industrial system.

Copyright © All rights reserved. WRT 2017

The system was also deployed in a Sonoma County winery to demonstrate reclamation of distilled water from high solids, high BOD, winery wastewater. Typical recovery for this application was 95%. Product TDS was less than 30 ppm.

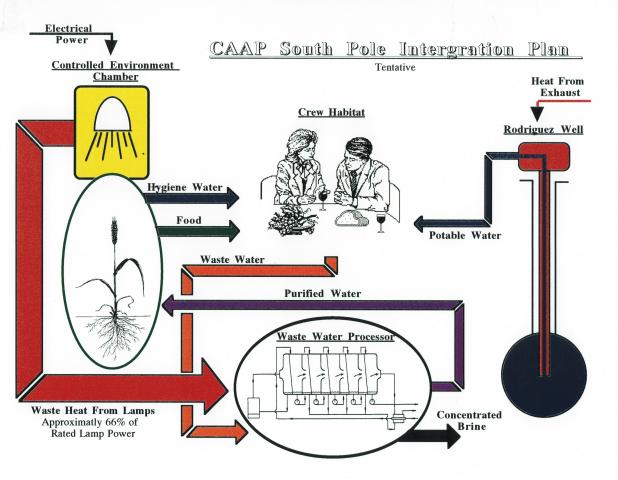

WRT built this 5-effect Vapor Compression Distiller for NASA to be installed at their South Pole research Facility. Waste water from crew habitat would be purified, and used to provide make up water for the crop growth chamber. Heat from the chamber lamps would be used to thermally drive the distiller. In the event that heat was not available, the system could be switched to operate solely on electrical power - using the vapor compression process.

Concentrated brine by-product from gas well produced water.